TFC series is a front-end mounted telescopic single effect tipping hoist specifically designed for the UK tippers.

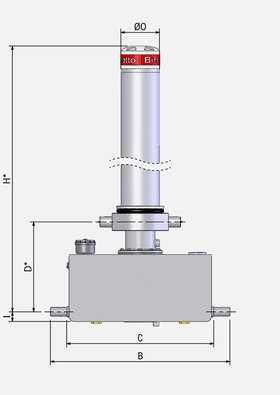

The outer cover tipper body hoist is combined with, and directly mounted on, the oil tank offering a unique system dedicated for rigid vehicles from 7.5 to 36 ton GVW.

Featuring B3 technology, TFC series single effect tipping hoists provide all the benefits of the exclusive Binotto design, including the cushion system during the stage transitions. The cylinder design is strong, stable and safe: it increases the working life of the system and has a minimal whole life cost.

This system offers operators a high pressure tipper body hoist that has a fast tipping cycle and it is safe, strong and reliable.

With its innovative design, bespoke bracketry and accessories, installation is also simple and has the benefit of the hydraulic valve being located on the top of the oil tank for easy access.

* including 20 mm pull-out

With the highest standards of product design, machining accuracy and material quality, Binotto TFC single effect tipping hoists offer a unique combination of operating benefits.

TFC Front End Cylinders are manufactured from premium grade steel with high yields point and tensile strenght, using seamless “one piece” tubing with integrated stop-ring contact faces and high performance seals to maximize the product quality.

The 'Roller Burnishing' process adapted by Binotto is applied to each seamless cylinder stage, both inside and outside, increasing the superficial hardness up to 40%.

Our special high performance seal and wiper system is designed to operate on these particularly hardened surfaces, allowing clearances between cylinder stages never more than 0.07mm.

As a consequence, Binotto hydraulic cylinders provide better resistance to side loads and bending factors.

TFC series tipper body hoist is fit with conical shape locking top head for a perfect, robust and safe fixing of the outer cover.

The swinging collar allows 6° oscillation of the outer cover to accompany the irregular movements of the tipping body during the tipping operation, protect the cylinder and increase safety and stability.

Brackets are made in spheroidal (nodular) cast iron and are fitted with grease nipples for easier lubrication of the joint points and reduction of wear and tear.

On the external tube, TFC series is fit with a unique anti-rattle ring to avoid the shaking of the outer cover and any noisy sound.

Very precise tolerances and high machining accuracy make the difference of our cylinders which are designed and produced to provide unsurpassed performances even when working in tough conditions.

The 'Roller Burnishing' process also provide exceptional smoothness on the tube surface ( with a mirror effect as a standard). This is both elegant and functional feature, since it allows long-lasting seals lifetime (up to 3 times longer), reducing the wearing effects on the inner parts.

Also featuring a double seal system, Binotto cylinders reduce at the minimum the risk of oil leaking and, as a consequence, the downtime of the machine.

Binotto also offers a full range of high quality hydraulics components to be coupled together with your TFC series cylinder. Select genuine Binotto products for your hydraulic kit, ensuring higher performances, safety and durability.

Proven engineering expertise ensures a safe cylinder selection for your vehicle application: contact the Binotto team.